Holding High Standard

Since 1985

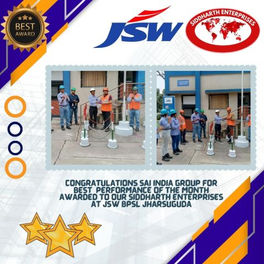

SAI INDIA GROUP & CO.

SHRI SAI INDIA ENGINEERING CO. | SAI INDIA ASSOCIATE | SIDDHARTH ENTERPRISES | SHRI SAI ENGINEERING

" OPERATIONAL & MAINTAINANCE SERVICES FOR INTEGRATED STEEL PLANT & POWERPLANT"

OUR ENGINEERING CONSULTING SOLUTIONS

Operation and Maintenance Services For Integrated Steel & Power Plants

Integrated Steel Plant complete operation & maintenance contract (O&M contract ).

All type of High-Skilled, Skilled, Semi-Skilled & Unskilled manpower supply for different areas of Integrated Steel Plants & Power Plant.

Maintenance (CM, PM & AM) of all type of EOT Cranes & Hoists with capacity from 2MT to 480 MT (Both ELECT & MECH).

Maintenance & Refurbishing job of Mechanical Equipment’s.

Supply of Technicians for various Electrical Maintenance mechanical. Maintenance,

Commissioning & Plant Operational Jobs.

All type of Mechanicals JOB Work. Fabrication & Erection Structure & pipe Lines (SS, ES & MS) .

All type of Material Handling Works through conveyor belts, bucket elevators, stackers, reclaimers, wagon tipplers, bridge type bucket wheel reclaimers, apron feeders, side arm chargers, rail pusher cars, vibratory feeders, mobile wagon loaders, cranes etc.

Operation & maintenance of outsourcing sintering, crushing proportioning & mixing etc.

Supply of industrial equipment (Hydra, Tipper, Hywa, dozer, Loader, Backhoe, Loader, Forklift).

Operation & Maintenance of Automobiles Equipment.

TRUSTED BY INDUSTRY LEADERS

Previously We had privilege to work in following Major Steel Plants:

-

LLYODS STEELS INDUSTRIES LTD– WARDHA-Maharastra, INDIA.

-

JSW STEEL COATED PRODUCT LTD,NAGPUR,MAHARASTRA, INDIA.

-

BHUSHAN STEEL LTD -ANGUL- Orissa, INDIA.

-

RAJENDRA STEELS- RAIPUR, CHATTISGARH, INDIA. BHUSHAN STEEL AND STRIP LTD, Maharashtra, INDIA.

-

NOVA STEELS, BILASPUR, CHATTISGARH, INDIA.

-

IND SYNERGY LTD,RAIGARH ,CHATTISGARH,

-

INDIA VEDIK ISPAT PVT LTD, HINDUPURAM, ANDRA PRADESH BHUSAN STEEL LIMITED – Khopoli, Maharashtra, INDIA